sol gel alumina coatings

①The colloidal particles are uniformly dispersed, transparent, and stable without agglomeration;

②The colloid contains positive charge, which is odorless, non-volatile and non-flammable;

③It is viscous, thixotropic, reversible in water, suspended and absorptive with super high SSA.

- Product Description

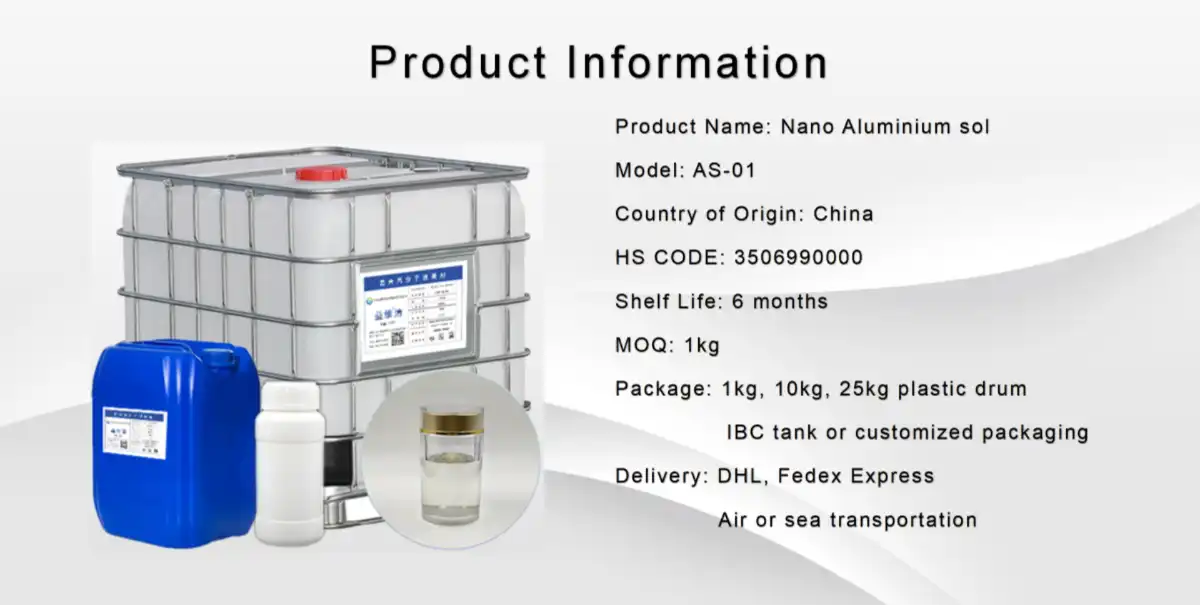

To facilitate your test, we offer free sample delivery service. Stock quantity is limited. First come, first served! Please contact sales@ywputai.com to get!

Welcome to Xi'an Yiwei Putai Environmental Protection Co., LTD, your trusted manufacturer and supplier of high-performance sol-gel alumina coatings. With over 16 years of experience in environmental protection and materials science, we're proud to offer cutting-edge sol gel alumina coatings that provide superior wear resistance, corrosion protection, and thermal stability. Our advanced formulations and state-of-the-art production facilities ensure top-quality coatings tailored to meet the demanding needs of aerospace, automotive, and industrial applications.

Product Description

Our sol gel alumina coatings are engineered to deliver exceptional surface protection and enhancement across a wide range of substrates. Using advanced sol-gel technology, we create ultra-thin, uniform layers of alumina that bond seamlessly with the base material, providing unparalleled durability and performance.

Product Specifications

| Property | Value |

|---|---|

| Coating Thickness | 0.5 - 5 µm |

| Hardness | 9+ Mohs scale |

| Temperature Resistance | Up to 1200°C |

| Chemical Resistance | Excellent against acids and alkalis |

| Adhesion Strength | >70 MPa |

| Porosity | <0.5% |

Why Choose Our sol gel alumina coatings

- Exceptional wear and corrosion resistance

- Superior thermal stability in extreme environments

- Excellent adhesion to various substrates

- Ultra-thin, uniform coating application

- Customizable formulations for specific industry needs

- Environmentally friendly, solvent-free process

- Cost-effective long-term protection solution

Certifications

- ISO 9001:2015 Quality Management System

- ISO 14001:2015 Environmental Management System

- RoHS Compliant

- REACH Registered

Product Advantages

Our sol gel alumina coatings offer a unique combination of properties that set them apart from traditional coating solutions:

- Nanoscale precision: The sol-gel process allows for molecular-level control, resulting in exceptionally uniform and dense coatings.

- Low-temperature application: Unlike traditional ceramic coatings, our sol-gel process can be applied at much lower temperatures, preserving the substrate's properties.

- Versatility: Our coatings can be applied to a wide range of materials, including metals, ceramics, and even some polymers.

- Enhanced durability: The strong chemical bonding between the coating and substrate ensures long-lasting protection under harsh conditions.

Sol gel alumina coatings Application Areas

- Aerospace components

- Automotive engine parts

- Industrial machinery and equipment

- Electronics and semiconductor manufacturing

- Medical devices and implants

- Energy sector (e.g., turbine blades, solar panels)

- Optical lenses and precision instruments

Customer Cases

We've successfully implemented our sol gel alumina coatings in various industries:

- Aerospace: Improved turbine blade lifespan by 30% for a major aircraft engine manufacturer.

- Automotive: Reduced wear on cylinder liners by 40% for a leading car manufacturer, increasing engine efficiency.

- Industrial: Extended the service life of chemical processing equipment by 50% for a petrochemical company.

Technical Support and Services

Our team of expert engineers provides comprehensive support throughout your project:

- Custom formulation development

- On-site application training

- Quality control and testing services

- Ongoing technical consultation

FAQ

Q: How long does the coating process take?

A: The coating process typically takes 24-48 hours, including curing time.

Q: Can sol gel alumina coatings be applied to complex geometries?

A: Yes, our coatings can conform to intricate shapes and surfaces due to their liquid precursor state.

Q: What's the expected lifespan of your coatings?

A: Depending on the application, our coatings can last 5-10 years or more under normal operating conditions.

Contact Us

Ready to enhance your products with our advanced sol gel alumina coatings? Contact our sales team today for a consultation and free quote. Email us at sales@ywputai.com. Let's work together to find the perfect coating solution for your needs!

_1729152910684.webp_1736328486701.webp)